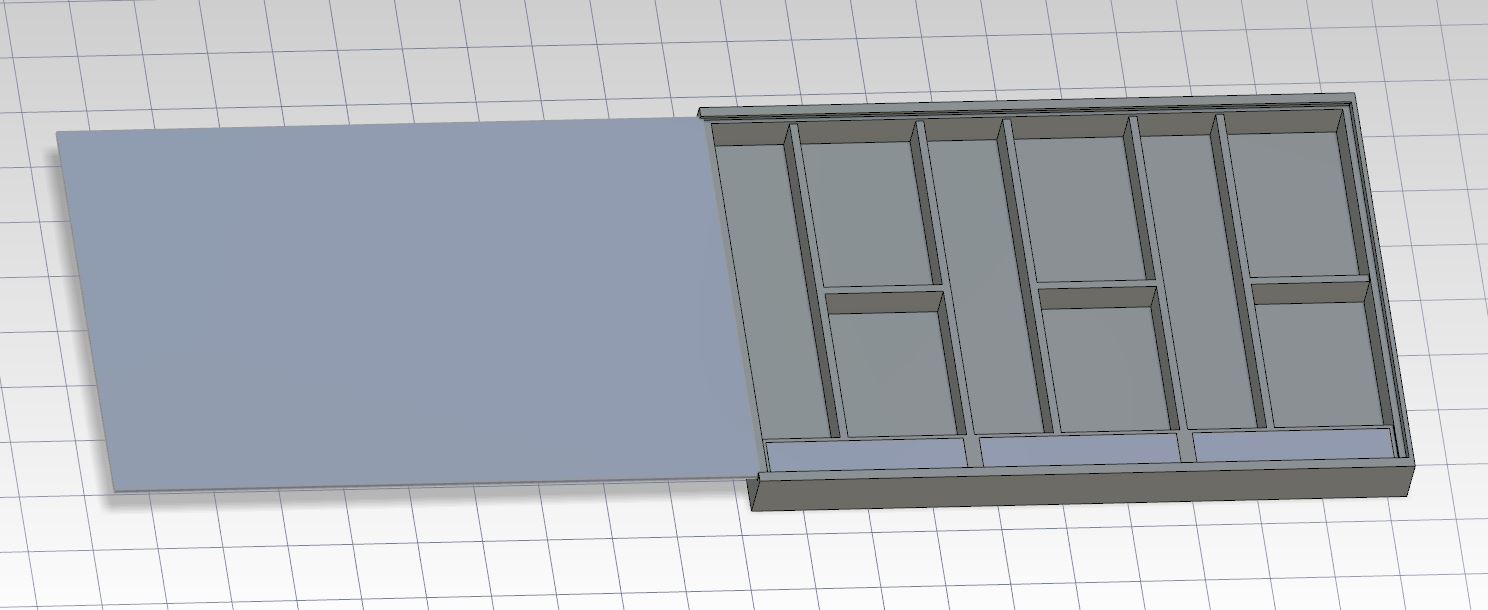

You definately need to add an instruction manual to the box or lazer engrave it to the inside of the box.

RiceMaiden's Hangar of Ship Models

- Thread starter RiceMaiden

- Start date

-

- Tags

- ships

Present that to their legal department, please, because I'd love for you to be licensed for that! I'd buy one immediately. Gotta do a plastic parts (injection mold) version. If licensed, can kickstarter the funds to get the aluminum molds made, then partner with a company with an injection mold machine. Boom bam! done!I've got beer, sunshine and some models to build!

They probably would but only for small/limited runs with low profits. I'm not tooled up to make more than one/two off units... and I would need ongoing profits to help pay for improved tooling. It's just not a sound way to increase my capabilities.God damn you need to see if CIG will license(reverse license?) this and sell them.

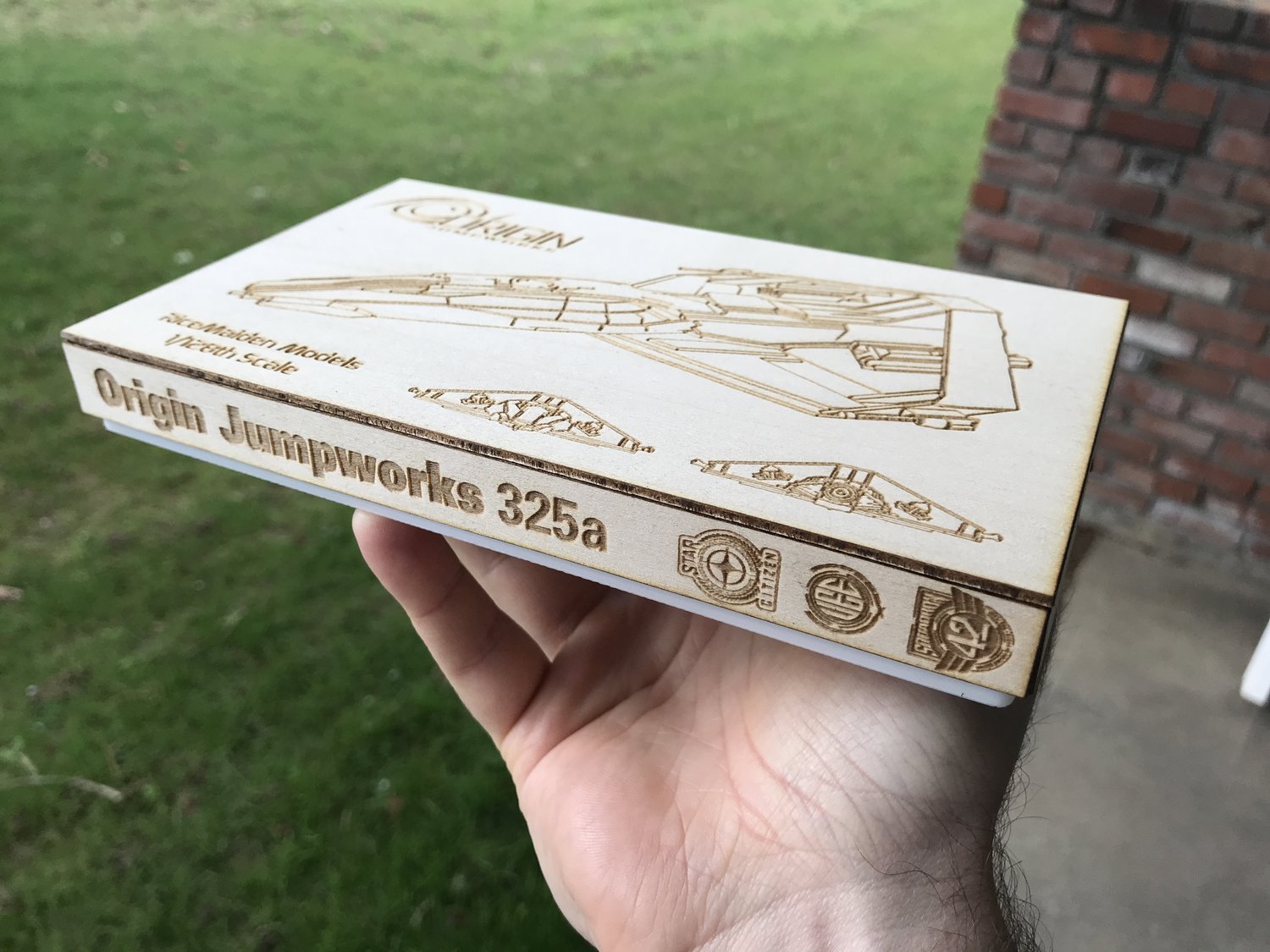

I am working with a company up in Portland on the laser cut parts. If I can get the prices low enough, then I might consider contacting them for a small run.

While it's a good idea, the members that have built my models outside of me have been provided with a 3D PDF. It's just easier to see the full 3D model and spin it around, hide parts, etc, etc.You definately need to add an instruction manual to the box or lazer engrave it to the inside of the box.

Even professionally, I rarely design and build tools beyond the first ~5 prototypes. That coupled with my relatively conservative methods to business and money make the prospect of approaching build 4 sale ship models a bit cumbersome. I'd do a very low run first and build from their. I'm not sure it would ever get the level of needing injection molding... but who knows.Present that to their legal department, please, because I'd love for you to be licensed for that! I'd buy one immediately. Gotta do a plastic parts (injection mold) version. If licensed, can kickstarter the funds to get the aluminum molds made, then partner with a company with an injection mold machine. Boom bam! done!

Apologies.More please

Actually that was a bit harsh. I'm still working on the Polaris and should probably finish it before I run out of wood again.More please

haha Ah you didnt mention there was a 3D PDF that really helps and i would consider that a set of instructions.They probably would but only for small/limited runs with low profits. I'm not tooled up to make more than one/two off units... and I would need ongoing profits to help pay for improved tooling. It's just not a sound way to increase my capabilities.

I am working with a company up in Portland on the laser cut parts. If I can get the prices low enough, then I might consider contacting them for a small run.

While it's a good idea, the members that have built my models outside of me have been provided with a 3D PDF. It's just easier to see the full 3D model and spin it around, hide parts, etc, etc.

Even professionally, I rarely design and build tools beyond the first ~5 prototypes. That coupled with my relatively conservative methods to business and money make the prospect of approaching build 4 sale ship models a bit cumbersome. I'd do a very low run first and build from their. I'm not sure it would ever get the level of needing injection molding... but who knows.

Apologies.

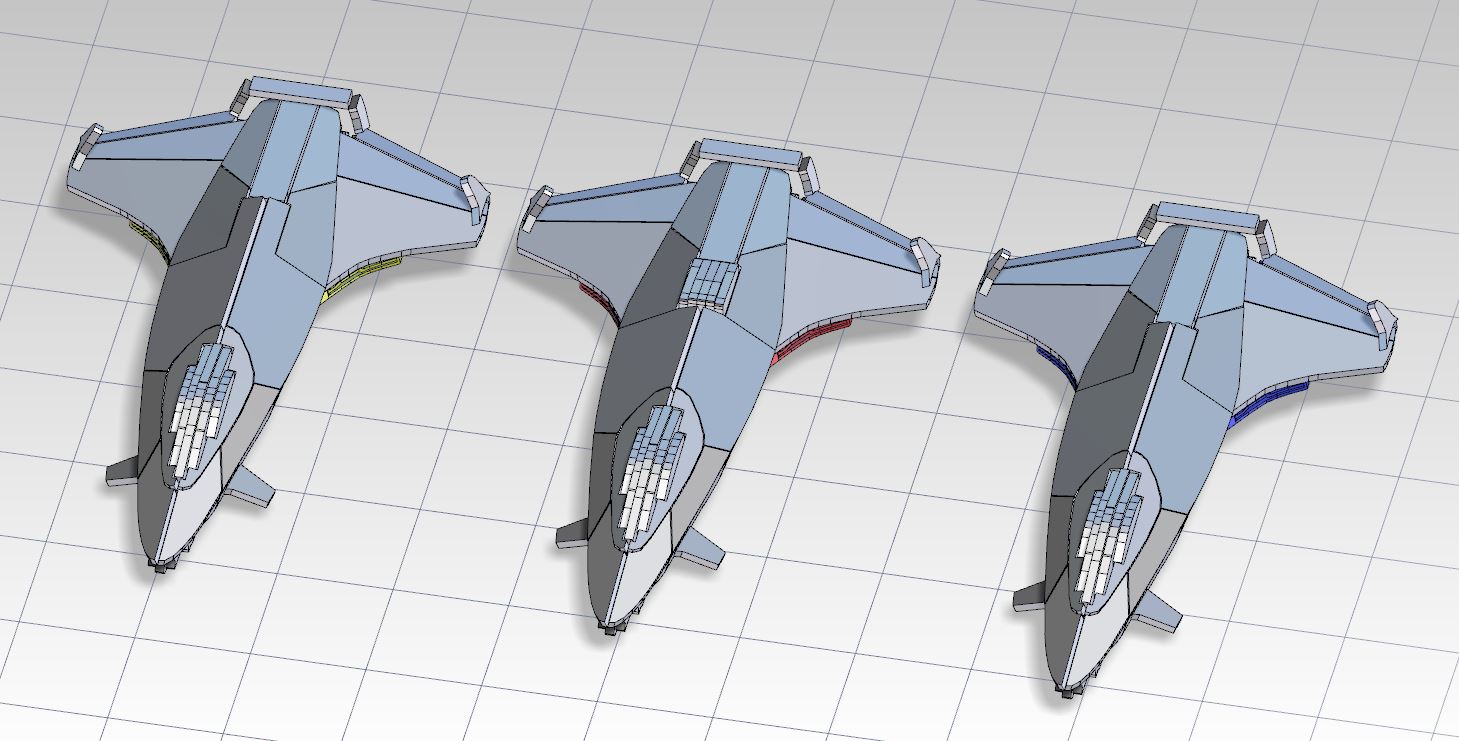

Some updates! (apologies, I've had a lot to drink tonight)

Cutlass:

In @Gearen crushing fashion, I started on a different model. The reworked Cutlass Black will be realized soon!

Polaris:

In @Gearen crushing fashion yet again, the Polaris is still stuck at like 60% done.

Blade:

I need to get this done for my own fleets sake. I'm in the repair the model phase right now. Most of this model will be 3D printed like the Nox was.

Idris M:

~20% done. Needs time and love.... but soooooooooooooon (like 2 years).

Gladius:

Coming along well. Needs some time (plus I'm 6 months past owing it to a friend)

Scythe:

Shouldn't take too long. The revisions of what I have are done. Just needs the distortion cannon wing made

Terrapin:

The waifu owns one. Probably should finish it.

Cutlass:

In @Gearen crushing fashion, I started on a different model. The reworked Cutlass Black will be realized soon!

Polaris:

In @Gearen crushing fashion yet again, the Polaris is still stuck at like 60% done.

Blade:

I need to get this done for my own fleets sake. I'm in the repair the model phase right now. Most of this model will be 3D printed like the Nox was.

Idris M:

~20% done. Needs time and love.... but soooooooooooooon (like 2 years).

Gladius:

Coming along well. Needs some time (plus I'm 6 months past owing it to a friend)

Scythe:

Shouldn't take too long. The revisions of what I have are done. Just needs the distortion cannon wing made

Terrapin:

The waifu owns one. Probably should finish it.

and a toilet that flushes?Keep em comming rice! will the cutlass have a door that can actually slide?

Only if i can use it... in that case.... you know you could buy an RV then build a cutlass from it.and a toilet that flushes?

only if you are fine with a square tolietand a toilet that flushes?

Its 2948...I'm sure I can have my ass modified to fit the toilet.only if you are fine with a square toliet

Sexy........

Also i would wait on that blade since the new model they are doing changes the exterior a lot

Shadow Reaper

Space Marshal

Rice, I am still clueless as to the process you use. How do you get the basic geometry for each ship so perfect? I get there is much art and craft in figuring out how to fashion the form you find, but are you actually drawing the basic form or does it come from some file CIG provides?

For the most part I use CIG's holoviewer and in-game models as templates. I build my parts inside and around the official geometry so that I maintain the intended shape and scale.Rice, I am still clueless as to the process you use. How do you get the basic geometry for each ship so perfect? I get there is much art and craft in figuring out how to fashion the form you find, but are you actually drawing the basic form or does it come from some file CIG provides?

Beerjerker

Grand Admiral

These are really great, @RiceMaiden ! Thanks for sharing all the photos!

Not to add to your tasks to complete, but maybe you'd like some clear plastic tubes and make bases kind of like this:

(Note: Just found the picture, I did not make this!)

Not to add to your tasks to complete, but maybe you'd like some clear plastic tubes and make bases kind of like this:

(Note: Just found the picture, I did not make this!)

I will raise the question with CIG about doing a small, limited TEST squadron run. Something like 25 units in any variant you want. I would need written permission to do so.How much for a smal 125a with no box and not build in a postbag to Spain?

I could see if I could fit the parts in an envelope and ship it (I don't know what the rules are on envelopes that don't lay flat)... otherwise it's a flat rate padded envelope for $32. I could see how many I could fit in one of the flat rate envelopes if you wanted to re-mail the kits once they were in Europe.

In the end it would probably be something like $5 a kit... 3 orders and split shipping and you'd be looking at about $15 USD per person to Spain.

Apologies on being slow on this. I have no doubt CIG would give me written permission for a limited, short run for TEST... but figuring out what to do with shipping overseas is an issue... I just don't feel right offering a $5 kit with $32 of shipping tacked on top.

Hey, i'd definitely want one, even with crazy shipping. Luckily, as a Canadian, shipping from the US usually isn't too bad.I will raise the question with CIG about doing a small, limited TEST squadron run. Something like 25 units in any variant you want. I would need written permission to do so.

I could see if I could fit the parts in an envelope and ship it (I don't know what the rules are on envelopes that don't lay flat)... otherwise it's a flat rate padded envelope for $32. I could see how many I could fit in one of the flat rate envelopes if you wanted to re-mail the kits once they were in Europe.

In the end it would probably be something like $5 a kit... 3 orders and split shipping and you'd be looking at about $15 USD per person to Spain.

Apologies on being slow on this. I have no doubt CIG would give me written permission for a limited, short run for TEST... but figuring out what to do with shipping overseas is an issue... I just don't feel right offering a $5 kit with $32 of shipping tacked on top.